SSPA Upgrades MDL

With CompactRIO and LabVIEW™ for Instrumentation

The Challenge

MDL contains a large motor-controlled carriage that moves over a basin to either drive or trace vessels during testing. Although the carriage control and vessel Instrumentation systems are separated, the carriage control relies on real-time measurements from the instrumentation system.

Sensors and actuators for instrumentation are mounted on the vessel and varies for each setup. SSPA hosts a large collection of sensors that are individually traced with scaling and calibration information. The sensors communicate over a variety of interfaces, such as RS232, RS485, Ethernet EtherCAT, and PROFINET. To be able to keep up with the latest sensor technology, the instrumentation system has to allow easy integration of new sensors and sensor interfaces.

Some test setups, such as free-sailing vessels, require closed-loop control functions for rudder and thrust control. The instrumentation system must, therefore, support running closed loop control internally as well as communicating with external controllers.

Test scenarios are thoroughly planned at SSPA, so when operators hook up the system, they must be able to switch between configurations quickly and efficiently. In addition to configuration management, the operator must also be able to view live data during any measurement. WF Integration Services

All in all, the high ambitions for the new instrumentation system posed some tough requirements and challenges on performance, configuration, and usability.

Abstract

SSPA is a maritime consultancy company hosting unique testing facilities for physical validation of ship models. Their Maritime Dynamics Laboratory (MDL) has an 88x39m basin which can simulate a large variety of conditions, including wave generation. When it was time to upgrade the instrumentation, WireFlow’s competence and experience were used for developing the software framework controlling the hardware from National Instruments.

Figure 1. MDL at SSPA (image from www.sspa.se)

The Solution

Due to the variety of measurements that can be done in MDL, SSPA needed a highly flexibly system.

The new instrumentation is built around the 8-slot NI 9082 Compact RIO (cRIO) that can be fitted with IO from NI’s flora of C-series modules. The cRIO also has an FPGA for

Altogether, the system can log hundreds of channels simultaneously

To make use of the performance and various connectivity options for the hardware, a flexible, plugin-based software was developed for the cRIO. The main idea with a plugin-architecture is that the core software is built once, and new blocks are developed independently and picked up automatically when downloaded to the system. The user can expand the system with instrument drivers for new interface types, real-time models for closed-loop control, FPGA bit-files for high-speed logging or signal processing.

A separate HMI PC is used for configuration, control, visualization and log export. The HMI software is developed following the same principle of modularity and the user can create new panel types without having to recompile the code.

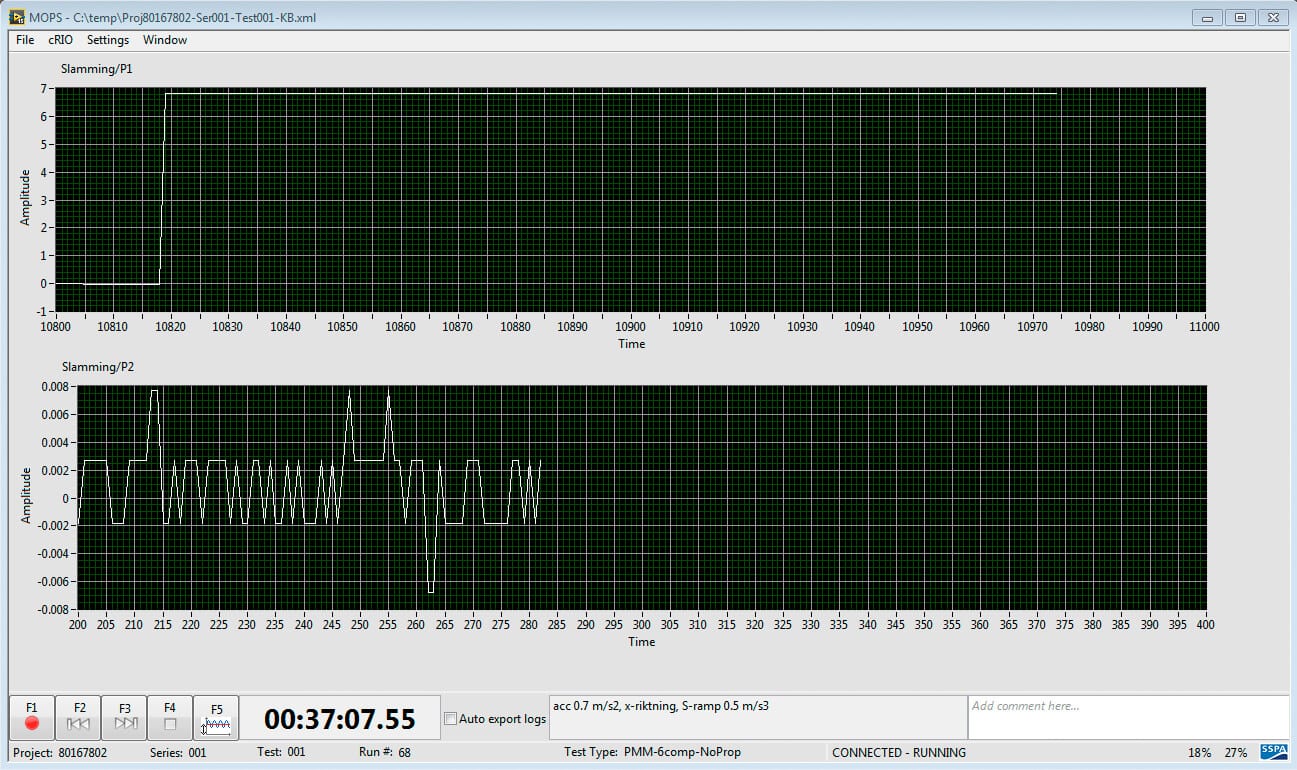

Figure 2. HMI Main Window

The system is configured in two levels to separate the tasks of test engineers and operators. This allows quick switching between different test scenarios.

Test engineers typically populate the system with expansion chassis and IO-modules. They create and edit the system configuration in the HMI to reflect the hardware setup. The system configuration is stored and can be retrieved if the hardware setup is altered.

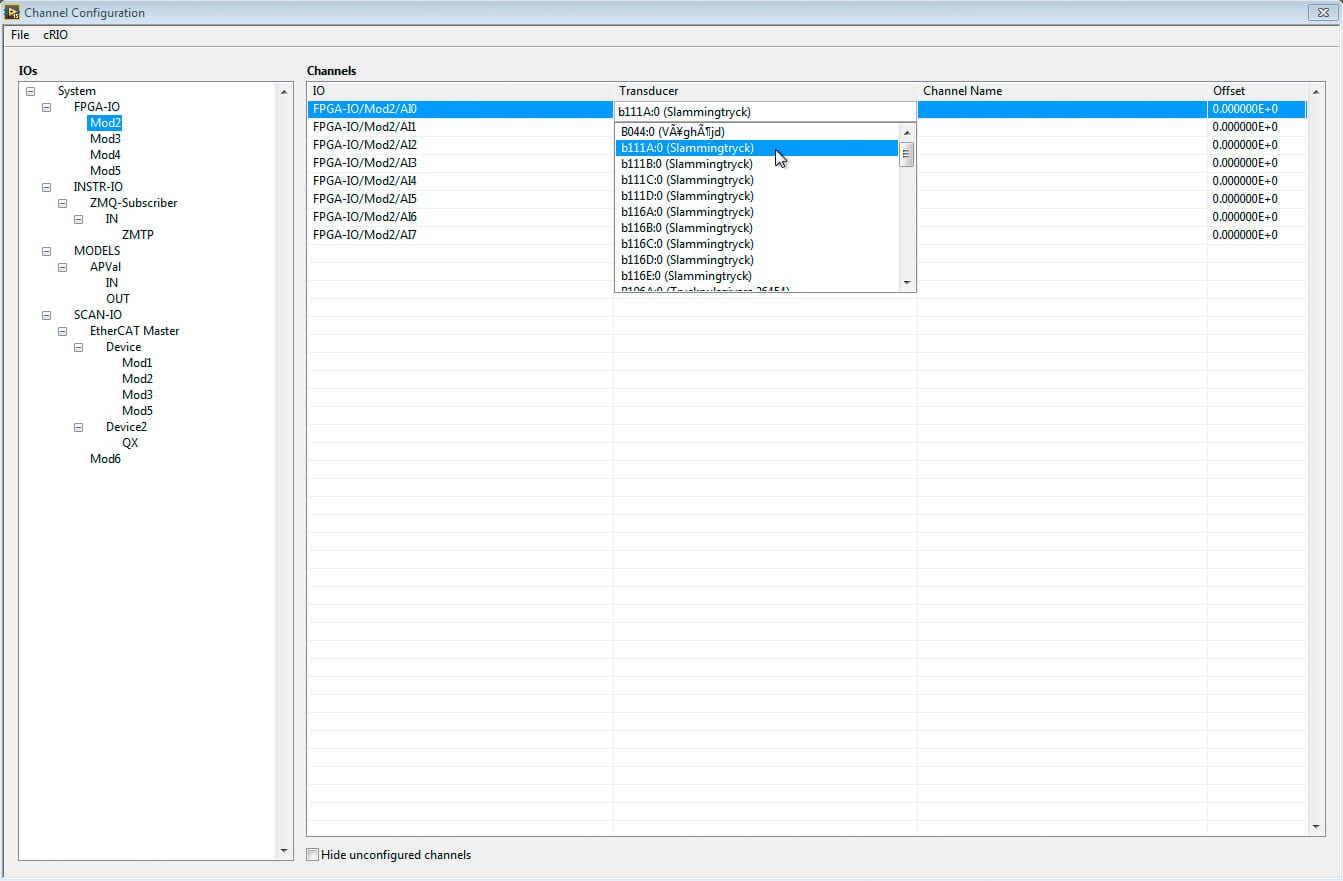

Operators can then select which sensors and actuators to use, which channel to connect them to and interconnecting channels to each other or to models (such as PID controllers). The resulting channel configuration is also stored and can be retrieved whenever the same test scenario is to be re-run.

Prior to sharp measurements, the user can take offset measurements to offset sensor inputs to match the current conditions. Offsets can be automatically exported to the channel configuration and edited manually.

The resulting log data can be up to several GB, so to economize on storage space the user can select which channels to export and crop data before exporting it.

Figure 3. Channel Configuration Window