Battery Test & Measurement

WireFlow Bifrost for your battery testing needs

Advances in batteries mean that battery manufacturers, integrators, second-life designers and recyclers are conducting more and more advanced tests on their batteries. Implementing and automating effective tests across the value chain is challenging. Test solutions are needed in all areas of development; including R&D, manufacturing, repurposing and recycling.

No two battery technologies are the same, and the test system must be able to adapt to different and changing needs. Wireflow’s battery test solution Bifrost can be tailored to your system requirements, ensuring that your unique innovations are thoroughly examined and optimized for success.

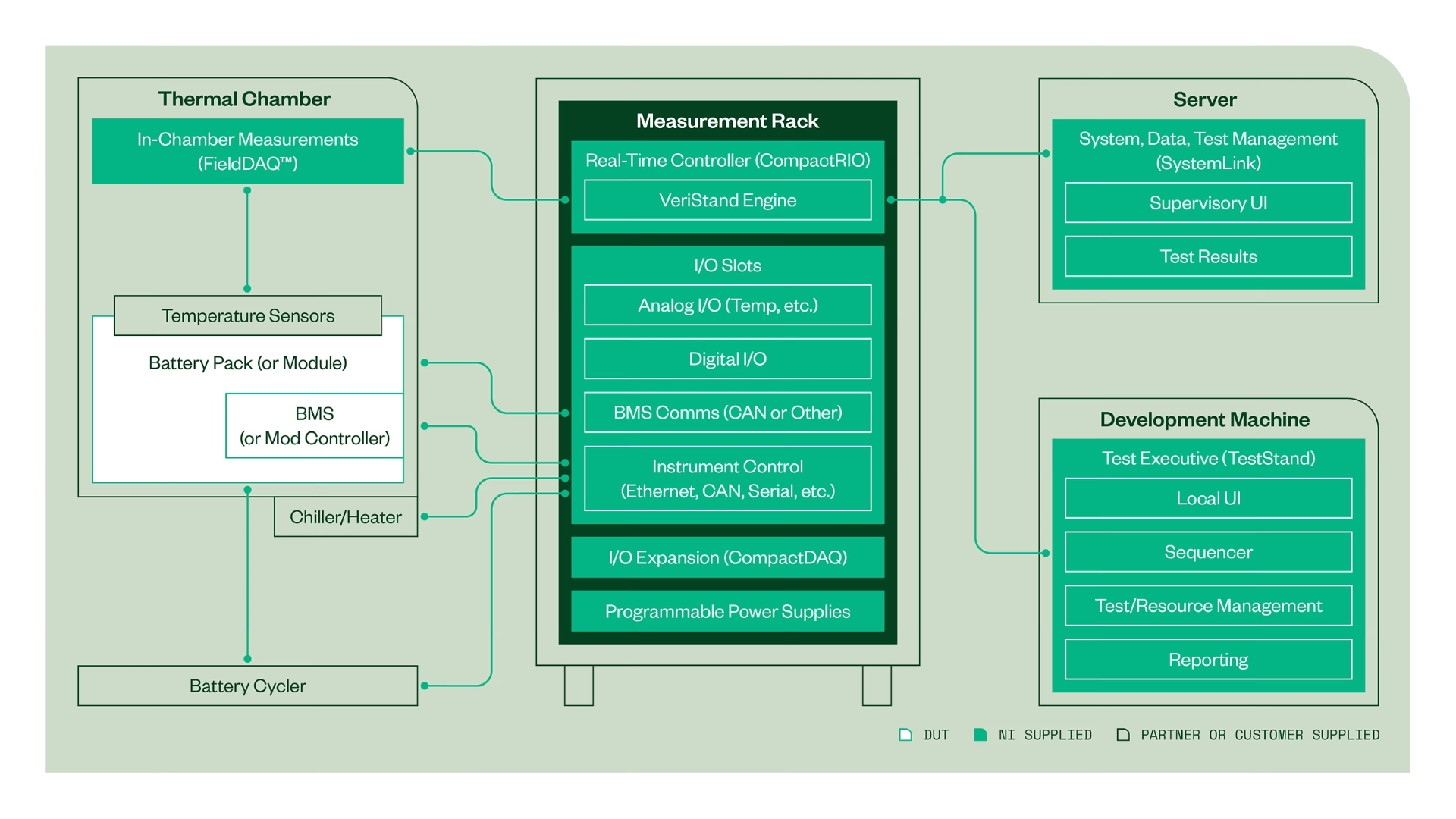

Bifrost is a highly configurable platform applicable to various test and measurement scenarios for battery systems. It is based on WireFlow’s extensive experience in battery applications and hands-on expertise in delivering robust test and measurement systems.

Bifrost includes a power cabinet with regenerative power supply units and distributed connection nodes, allowing the system to test multiple batteries simultaneously and independently, enhancing operational efficiency.

Do you want to know more about Battery Test & Measurement? Please contact us at info@wireflow.com

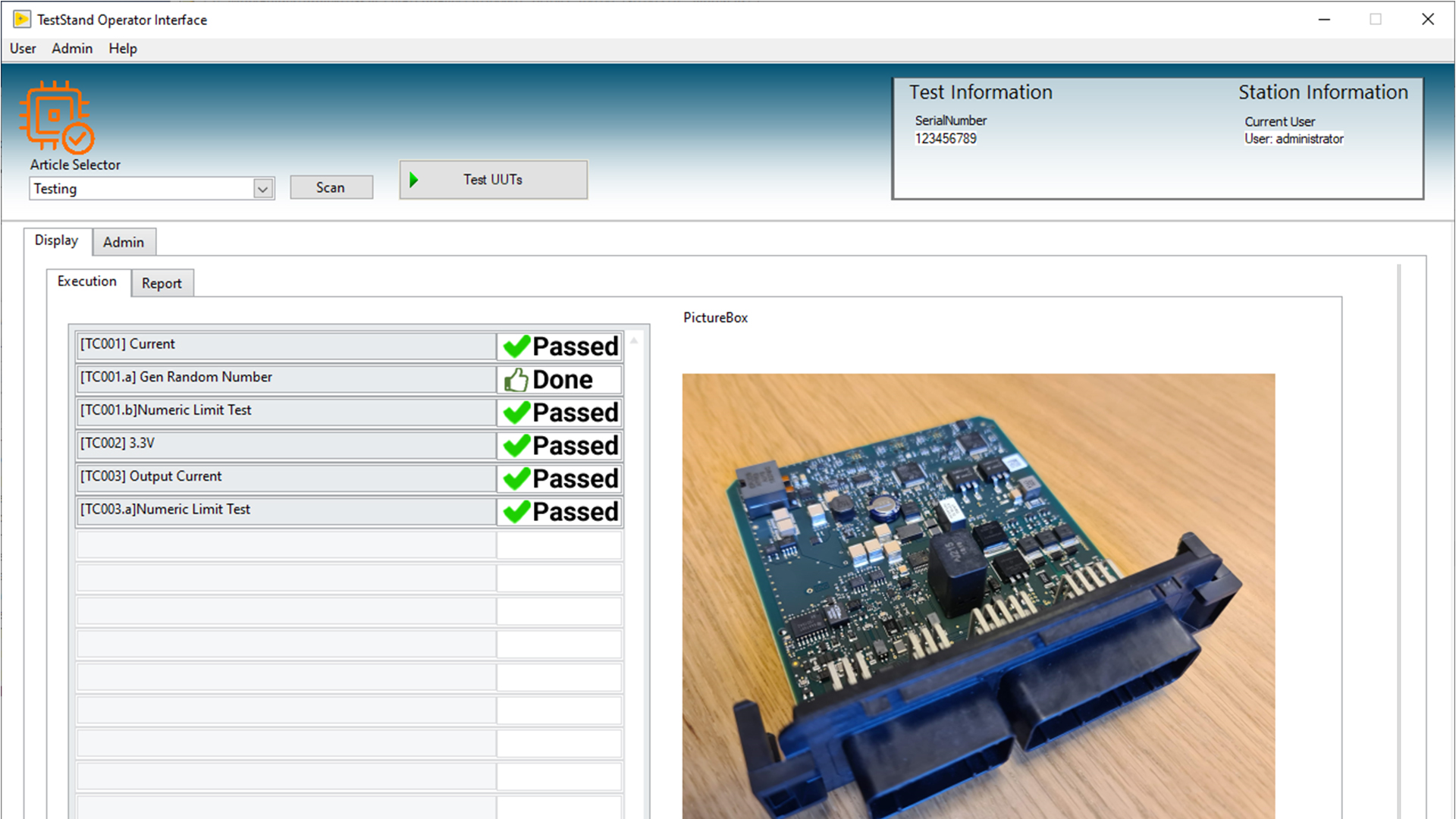

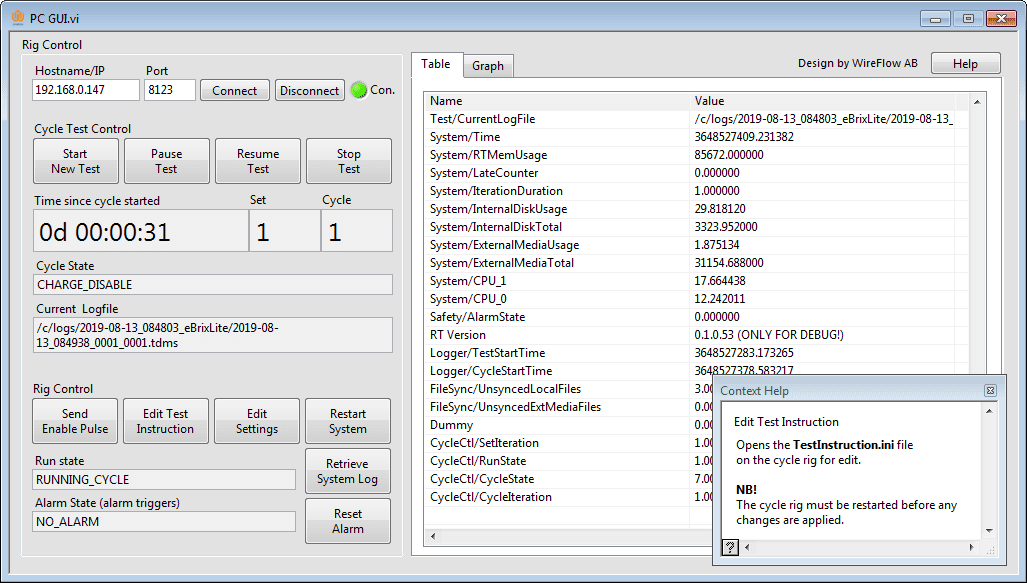

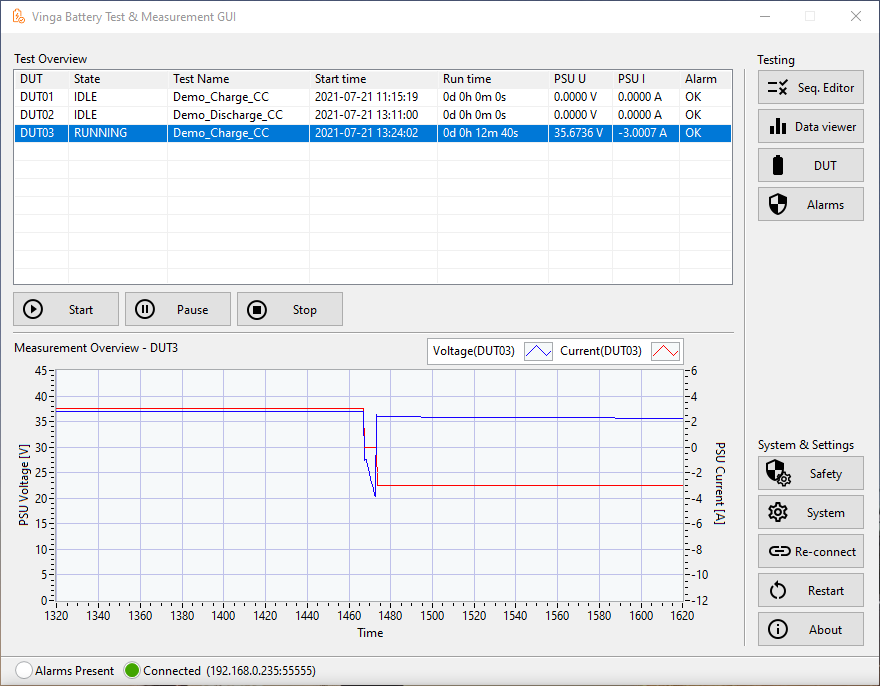

Operator panel for a battery cycle test rig.

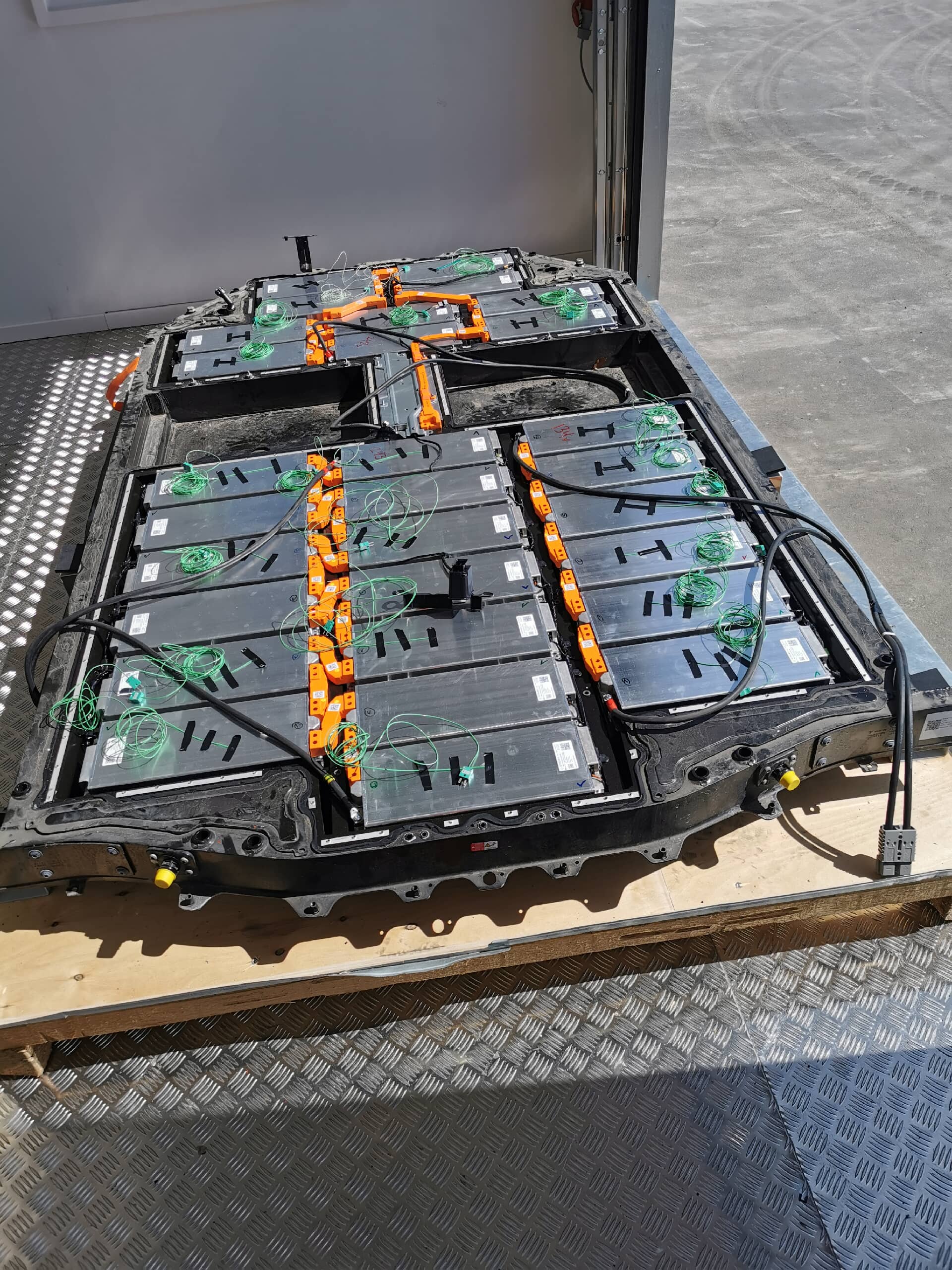

A charging and testing station for battery pack manufacturing.

WireFlow Battery Test & Measurement Systems

WireFlow Battery Test & Measurement Systems Presentation

WireFlow solution vertical for battery test and measurement. We provide of the shelf products and turn-key solutions for validation of cells and packs and production test of battery-packs.

WireFlow Battery Cycle Test Rigs

Solution for long term test and qualification of Li-Ion batteries.

WireFlow Battery Test & Measurement Solutions

WF Battery Test & Measurement

Research & development

Testing during battery development is critical to ensure performance, safety and reliability. Our battery testing systems cover capacity assessments, dynamic charge and discharge cycles, C-rate performance, and voltage profiles. This helps our customers understand and optimize different aspects for peak performance.

Our cycle life testing can simulate daily use, giving insights into battery endurance under different conditions. Flexible custom test scenarios helps researchers and developers identify potential areas for improvement, leading to more robust and dependable battery designs.

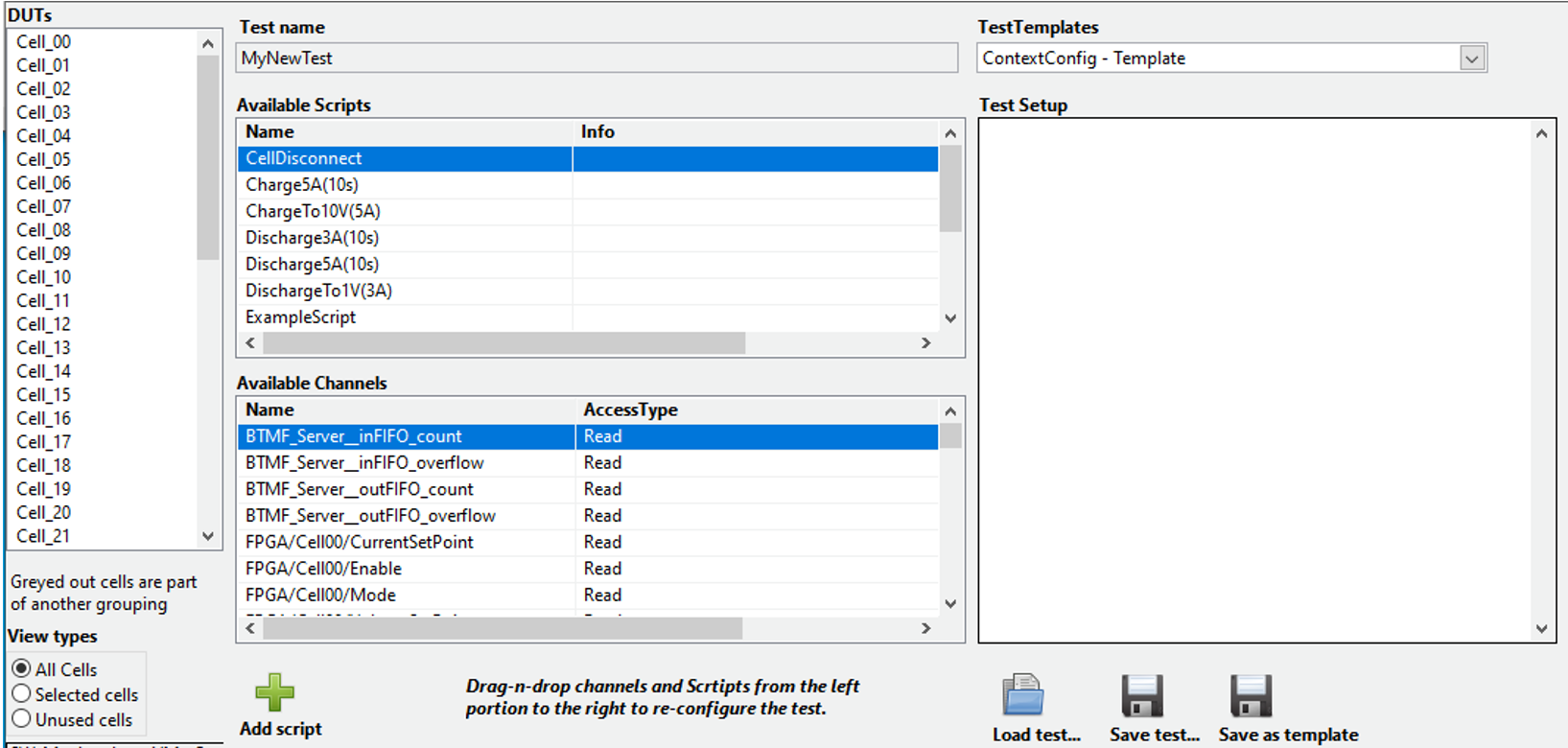

Bifrost Module and Pack testers are user-programmable, helping test engineers to do different types of “what if testing”. The system can be customized by WireFlow to fit the voltage levels, capacity, CAN communication etc. used by your battery pack.

WF Battery Test & Measurement

Recycling, Repurposing and Refurbishment

Whatever your goals for the refurbishment, repurposing, or recycling of batteries are; the Bifrost Module and Pack series is designed using input from multiple industrial customers to meet your needs.

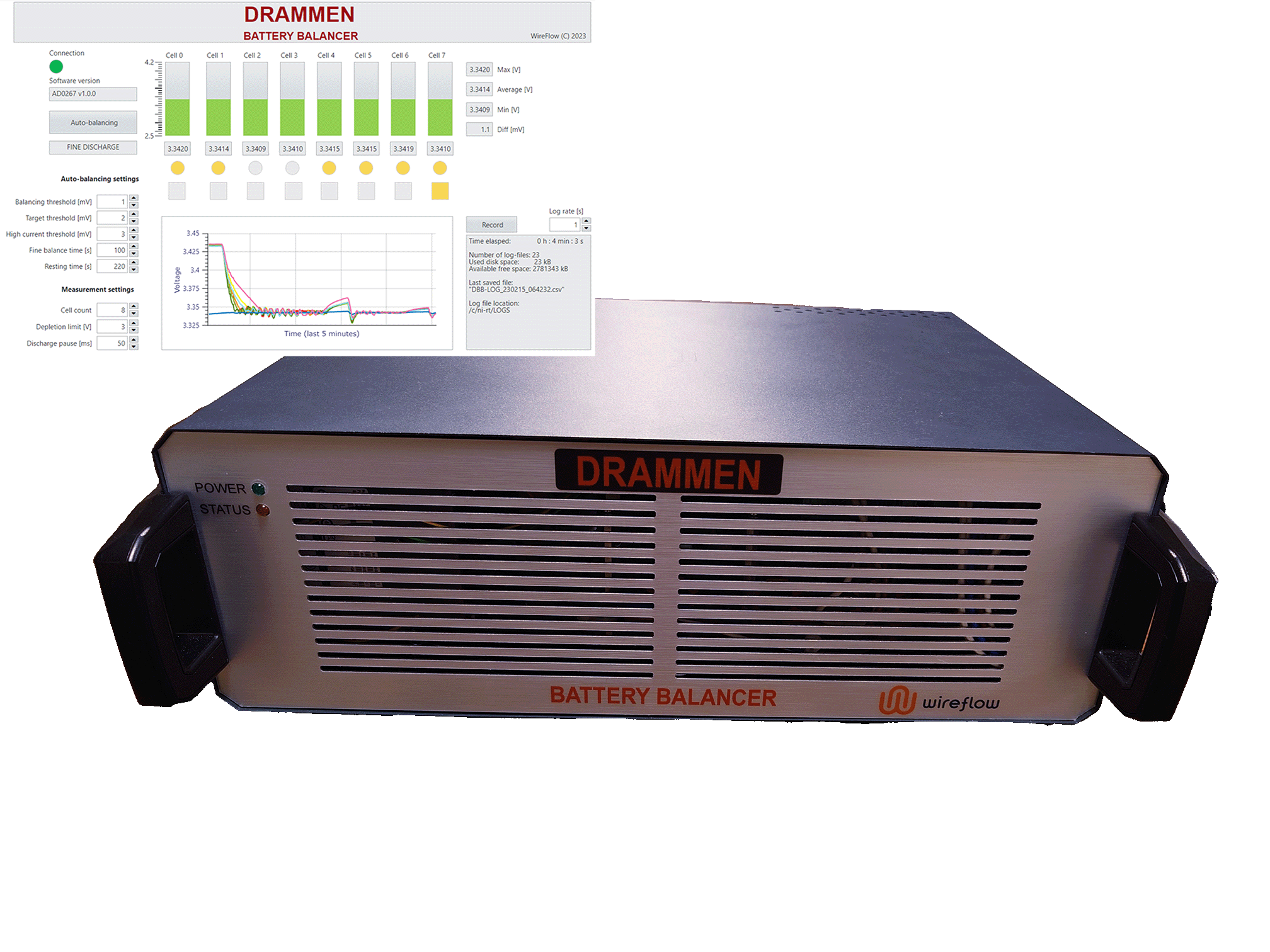

The Bifrost tester for repurposing, refurbishment, and recycling has a modular design to accommodate a wide range of voltage, current, and power requirements. Additionally, it is designed to perform a variety of tasks, including State of Health (SOH) assessments for characterizing and estimating remaining life, TotalDischarge™ for safe recycling, individual cell balancing, as well as charging and discharging for maintenance or transportation purposes.

WireFlow’s expertise in test and measurement, combined with in-depth battery domain knowledge, ensures safe and advanced operation, ultimately helping you save costs in the long term.

WF Battery Test & Measurement Systems

Production Testing and Charge for transportation

The WireFlow Bifrost systems are robust with a user-friendly interface, making them ideal for the demanding environment of the factory floor. Designed to handle high-volume production, these systems ensure consistent and accurate results.

Seamless communication with factory IT systems enhances efficiency, enabling precise programming and configuration for each battery pack. This integration minimizes errors and maintains uniformity across the production line.

The system executes a comprehensive functional testing protocol, evaluating fundamental functionalities beyond charging. This step provides an additional layer of quality assurance, ensuring each battery leaving the production line meets the highest standards of performance and reliability

Batteries are charged to the specified State of Charge (SOC). This ensures that the battery is charged according to the needs, whether for transportation or for assembly into a final product.

WF Battery Test & Measurement

Customized Battery Test Solutions

In addition to our standard systems based on the Bifrost platform, WireFlow can tailor a unique system to meet your specific needs. We have delivered cutting edge solutions to leading customers within the industry, where off-the-shelf products did not suffice, such as:

Building blocks

The building blocks is a collection of components that are used within the Battery Test & Measurement Solutions

Click on them for more information

More information coming soon for the building blocks below

Peripheral Software

Support Software

Label Printers

Hand Scanner

Read the case studies below about some of the projects that we have carried out in the past

CASE | WireFlow Integration Services

Charge and Test System for Li-Ion Battery

Toyota Material Handling Manufacturing Sweden is one of the world’s largest factories for manufacturing of warehouse trucks. Toyota was in progress of introducing a new generation of Li-Ion batteries for their trucks and needed new charging and test stations for the battery manufacturing line.

CASE | WireFlow Integration Services

Battery Cycle Test Rigs, A Solution for long term test and qualification of Li-Ion batteries

Micropower builds modular Li-Ion battery packs and chargers for a wide range of applications such as automotive, utility vehicles and mobile storage solutions.

They needed a safe, reliable and flexible test solution that could cycle battery packs unattended for many months, while logging large amounts of measurement data from the DUT (device under test).

CASE | WireFlow Integration Services

A Battery Testing Solution for Brompton Bicycle

Brompton Bicycle builds one of the most iconic foldable commuter bikes and is Britain’s largest bike producer. Upon introduction of their first electric bike to the market, they needed a top-of-the line battery testing solution.

Initially, the requirement was to test three packs, but the solution had to be scalable for easy upgrade to up to ten packs.

CASE | WireFlow Integration Services

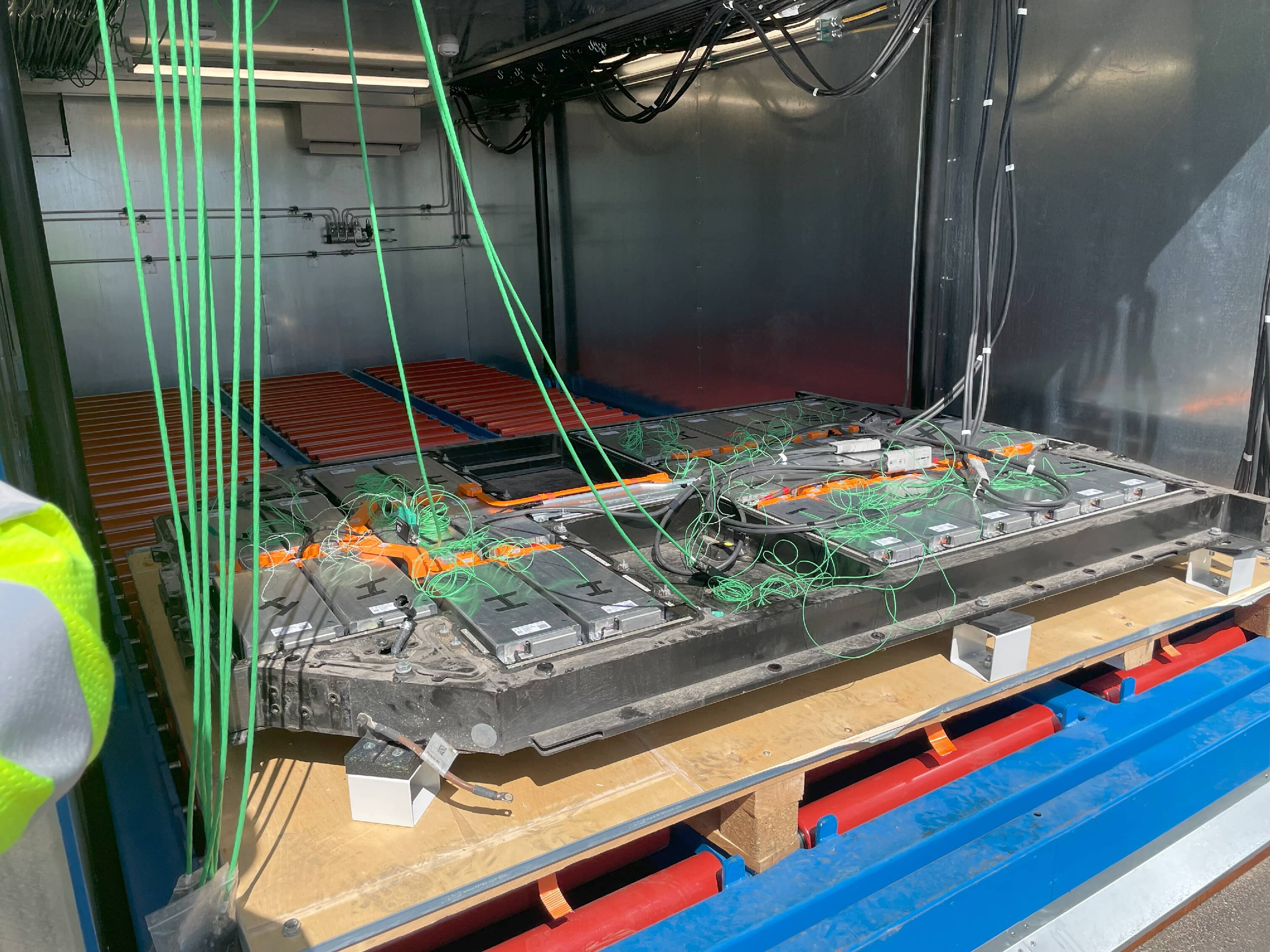

Donsö EV-Battery Reuse

and Recycling System

A WireFlow Bifrost Battery Test & Measurement solution for Stena Recycling which is a part of the goal to ensure that batteries can be repurposed, remanufactured, or recycled at the end of their life.

Want to see more

case studies?

Take a look at other case studies by clicking here.

Solution and Application notes

Downloads

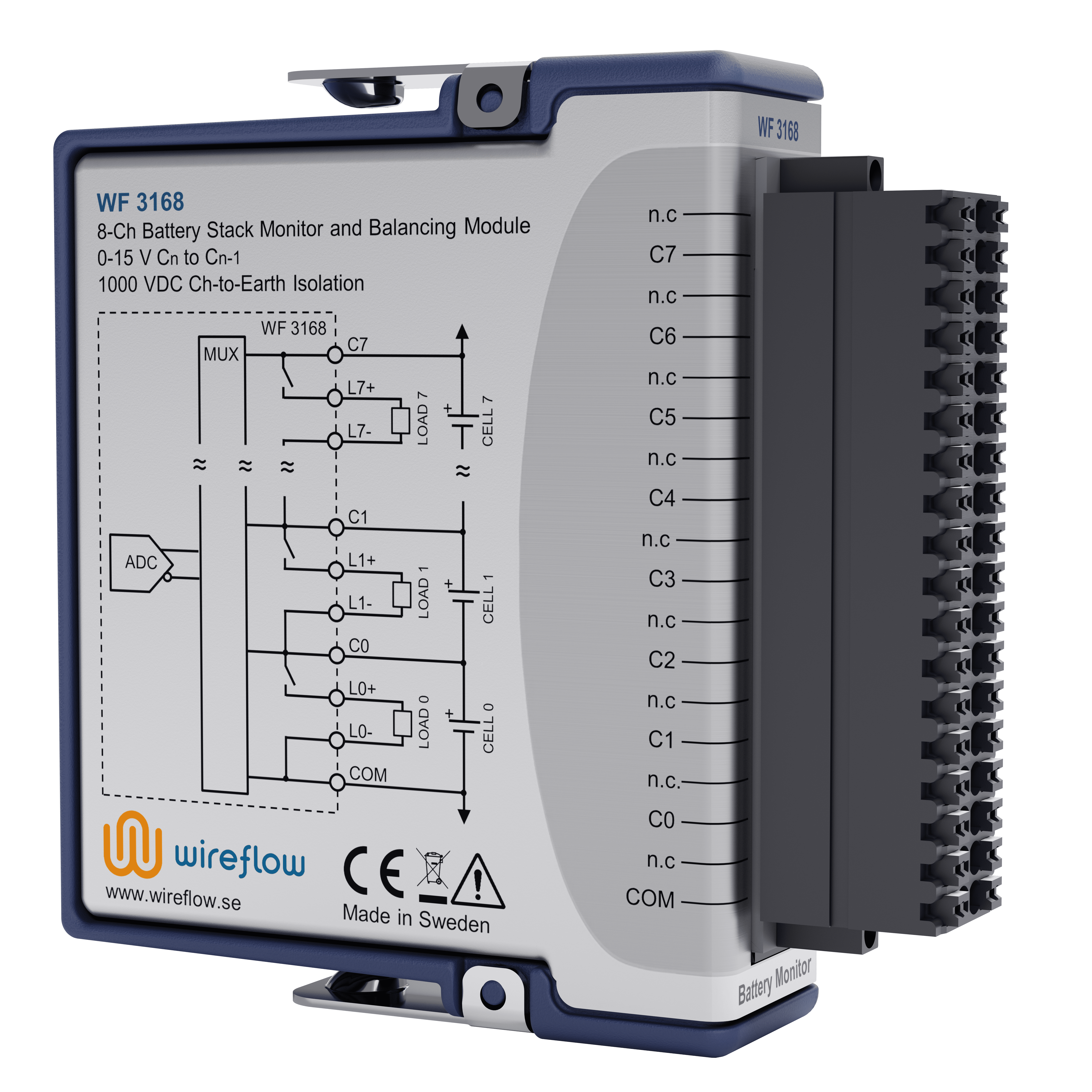

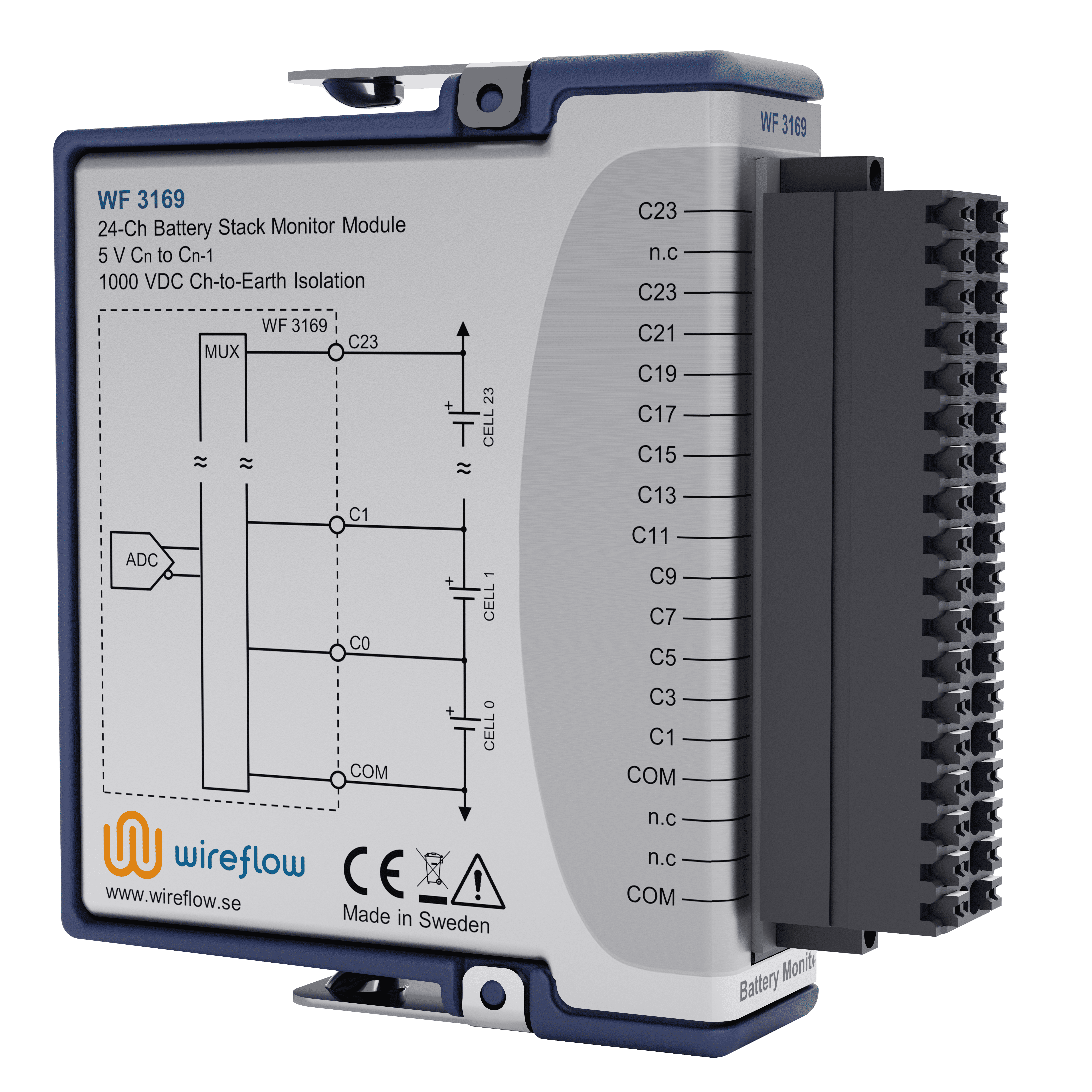

Measuring individual cells in high voltage battery packs

AB0005-116 AN19 Measuring individual cells in high voltage battery packs.pdf

Battery Stack Demo

AB0005-084 AN8 Battery Stack Demo.pdf

WF Bifrost Module Tester Series

AB0005-134, rev B Bifrost Module Tester Series.pdf