WR Controls uses LabVIEW and NI platforms for measurement

and data acquisition in R&D development

Abstract

This case study describes how companies such as WR Controls uses products from National Instruments in order to quickly set up data acquisition systems adapted to a different test of a variety of products.

Problem

WR Controls develops and produces a wide range of standard cables for industrial, marine and automotive business areas. All these cables are tested and

investigated for its mechanical properties. Forces, friction, and backlash properties are monitored in sometimes long time experiments in order to evaluate the reliability of the different components of the cables. WR Controls has a need of being flexible and adopt the tests rig to different environment and circumstances in order to tests and evaluate results early in the production cycle.

Solution

WR controls have chosen to work with hardware ( Figure 1) and LabVIEW software from National Instruments. The hardware, in this specific example, NI Ethernet RIO chassis, with a range of C-Series modules gives a flexible solution that can be adopted for different setups and types of measurements.

WR Controls frequently uses load cells for force measurements. These units can be connected to universal analog input modules (NI 9219) that can handle thermocouples, RTD, voltage and current measurements but has also support for a quarter, half and full bridge measurements with build in voltage and current excitation.

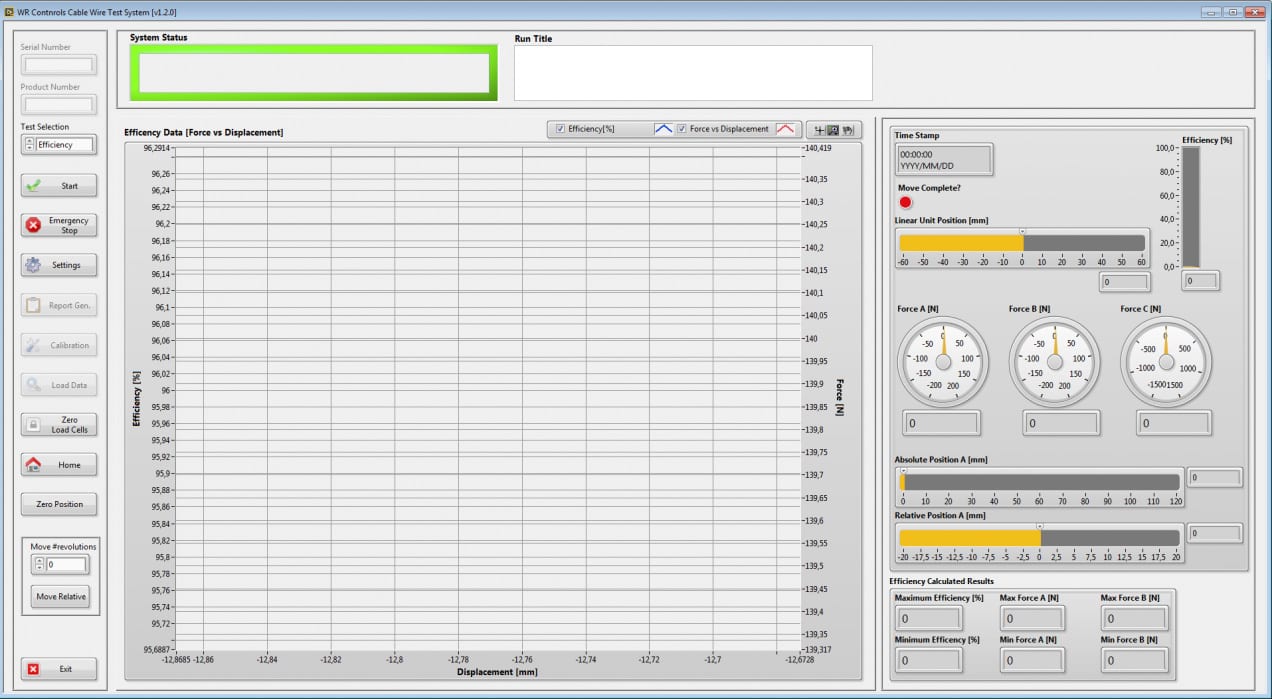

to the C-Series module 9512, the operator can control how the cable shall be pushed and dragged back and forth while the physical properties are continuously measured and monitored using the graphical user interface developed in LabVIEW, also shown in figure 3

WireFlow AB has in this collaboration helped WR Controls maintain the software and made future improvements and adaptions to new cable tests. The flexibility of the hardware and the graphical programming in LabVIEW makes it easy to make changes and include new functionality in the program.

The control software is installed on an ordinary windows computer as an *exe-fil which means that the customer does not need any licensed version of the LabVIEW development environment and can run the control program on several computers.