WireFlow Test Framework

Test expert services

To set up a complete environment can be quite a comprehensive task, especially if you haven’t done it before.

Production flow analysis and Test strategies

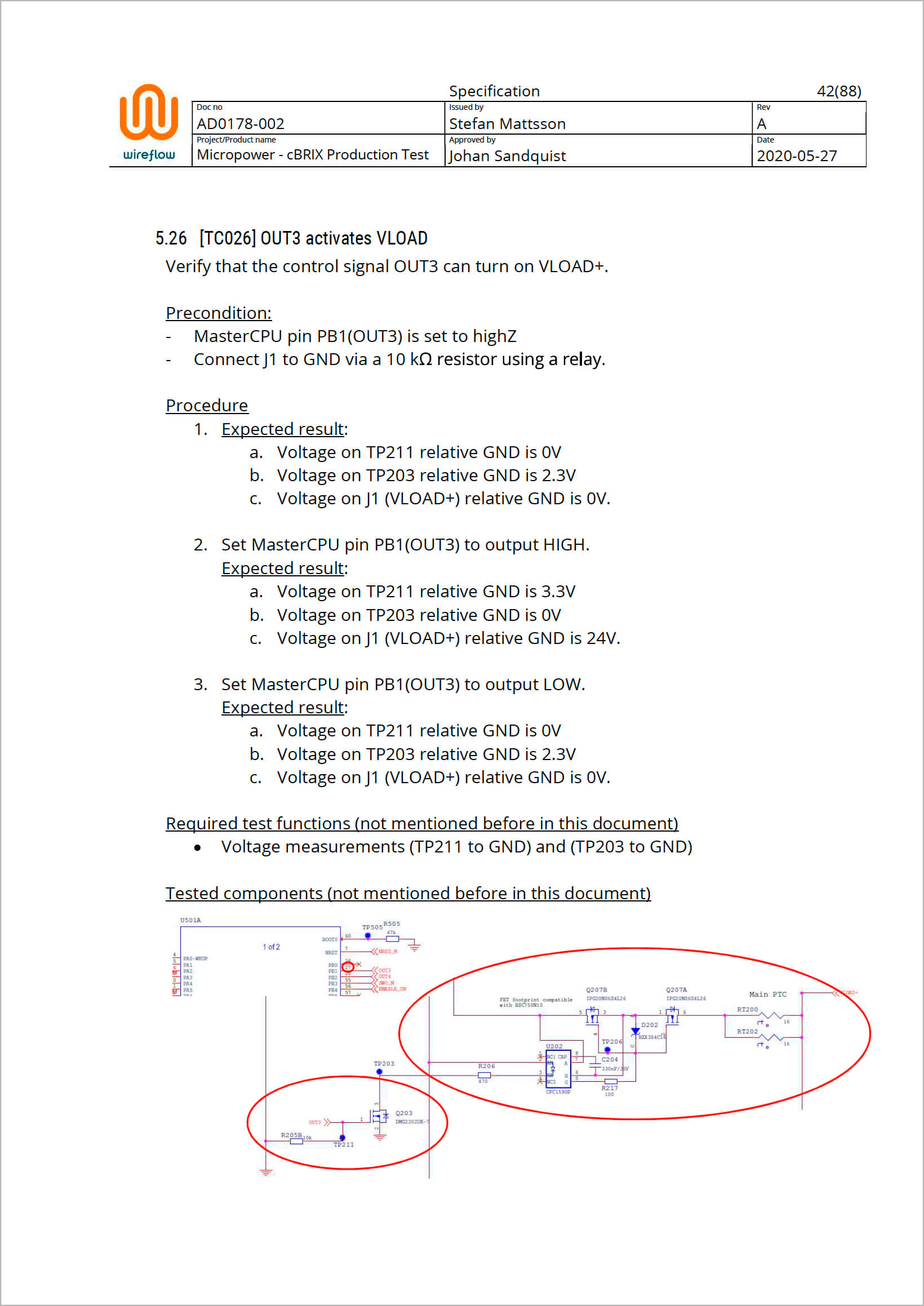

Together we can make a production flow plan for your product. When shall AOI be made? Shall coating be done before or after programming? What type of labels shall be used?

A good production flow plan gives a good base for further development of the production and test systems.

Test- and programming station in the factory

A production flow plan

What’s the best test strategy?

It is important to define a good test strategy in the early phases, one that decides what different types of testing shall be used; AOI, Boundary scan, ICT or Functional testing. Or maybe a combination of all these test methods shall be used?

Which test method to use depends on several factors. ICT is standardized and easy method to implement, however it requires many test points on the PCB. For boards with limited space, it might not be possible to add enough test points to make a complete ICT test. Also, it is not possible to test active components such as microcontrollers etc. by using the ICT method. This means that boards with limited space and/or active components will normally require Functional tests complemented with ICT tests of varying degree.

For boards with embedded processors, it is an important design choice to decide which type of software to use for functional testing; the standard software used by the product, special test software or perhaps Boundary scan?

Once a good strategy for test methodology is in place, the test system architecture can be defined. Here, we will investigate things like test fixture modularity, instrumentation, switching and multiplexing, embedded test functions etc.

In Circuit Testing (ICT): Small voltages are applied to strategic points on the board, and resulting values are measured. This requires access to the bare circuit board and is typically done in a needle-bed test fixture, where the un-powered board is mounted. ICT is optimal for testing components like resistors, capacitors and diodes.

Functional testing: This is a higher level of testing, where the powered circuit board is verified by testing its functionality. This testing is normally required for boards that include integrated circuits like voltage regulators, processors etc. It is not uncommon for a special test software to be executed on embedded processors to obtain good test coverage and fast and stable test cycles. For best test coverage, Functional testing should be combined with ICT.

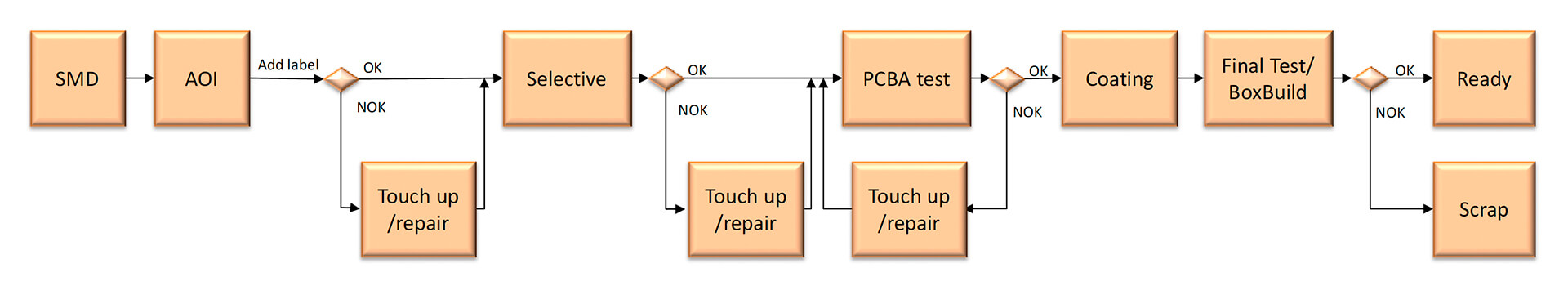

Label with product data

Product structure

Configuration management and serial number handling

When starting production of a new circuit board it is important to have good control of all design files, such as Gerber files, Bill of material and software hex files etc. A robust method for version handling and product structuring is vital to avoid the risk of shipping products with incorrect versions, or variants, to customers.

A well-defined product structure makes it easy to maintain the product design. The test system should also be designed and maintained in a version-controlled environment.

As part of product maintenance, serial number handling is vital. It can be a simple sequencer for generating the next free serial number, or it can be an advanced system where submodules are built together into larger assemblies, with full traceability.

WireFlow has extensive experience with configuration management and serial number handling and can assist you with setting up a system appropriate for either a small company, or for as integration of the production line with enterprise product management systems used by the large companies.

Testability analysis and test firmware programming

By studying the circuit diagram of your circuit board, we can propose where to put test-points in case the plan is to use a needle-bed fixture for testing the board.

If there are any microcontrollers on the board, we need to decide what software to run on the controllers during the test and programming phases. Here we have the alternative to use the standard software with or without special test modes. For example, can boundary scan be used? Or shall we develop a special firmware used for production testing?

WireFlow can assist you with everything from planning and writing test specifications to implementation of special firmware for the on-board controllers.

Source code for the embedded test application

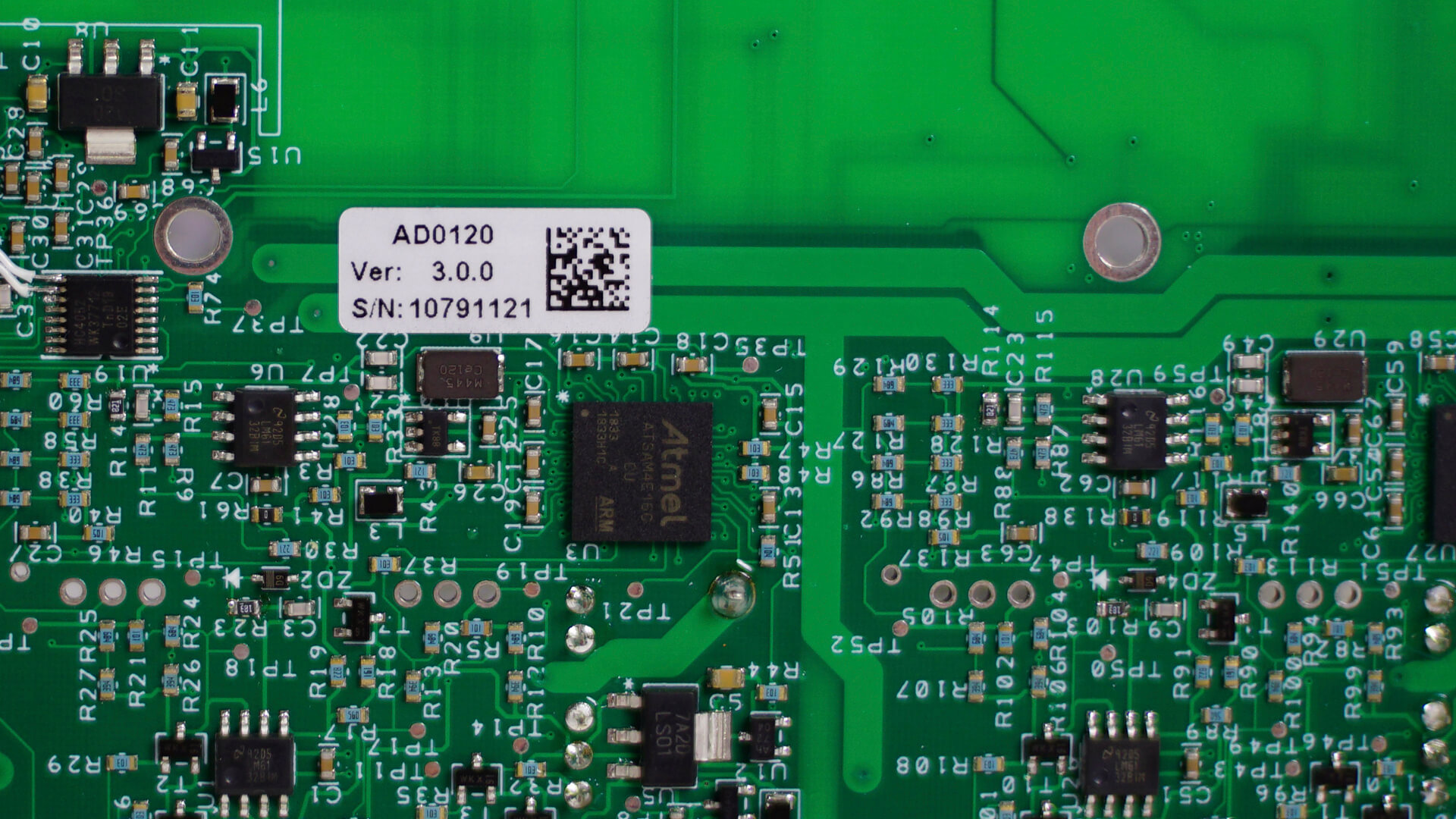

Test specification

Test specification

The test specifications define the procedures we use to test the circuit board. The goal is to ensure that all components have been mounted correctly on the PCB. We look for missing components, erroneous soldering etc. Input to the test specifications are the board schematics and Bill of material. The specification also aligns with the chosen test strategy regarding type of test, such as ICT and/or Functional testing. The test system architecture shall also be known when writing the specification.

The specification consists of a set of Test Cases that specifies what stimuli the test system shall send to the board under test and what the expected results are for each step of stimulation. The Test Case also specifies which components on the circuit board are being tested by the Test Case. So, if a Test Case fails, we can quickly pinpoint where on the board the problem is located.

Test sequence development

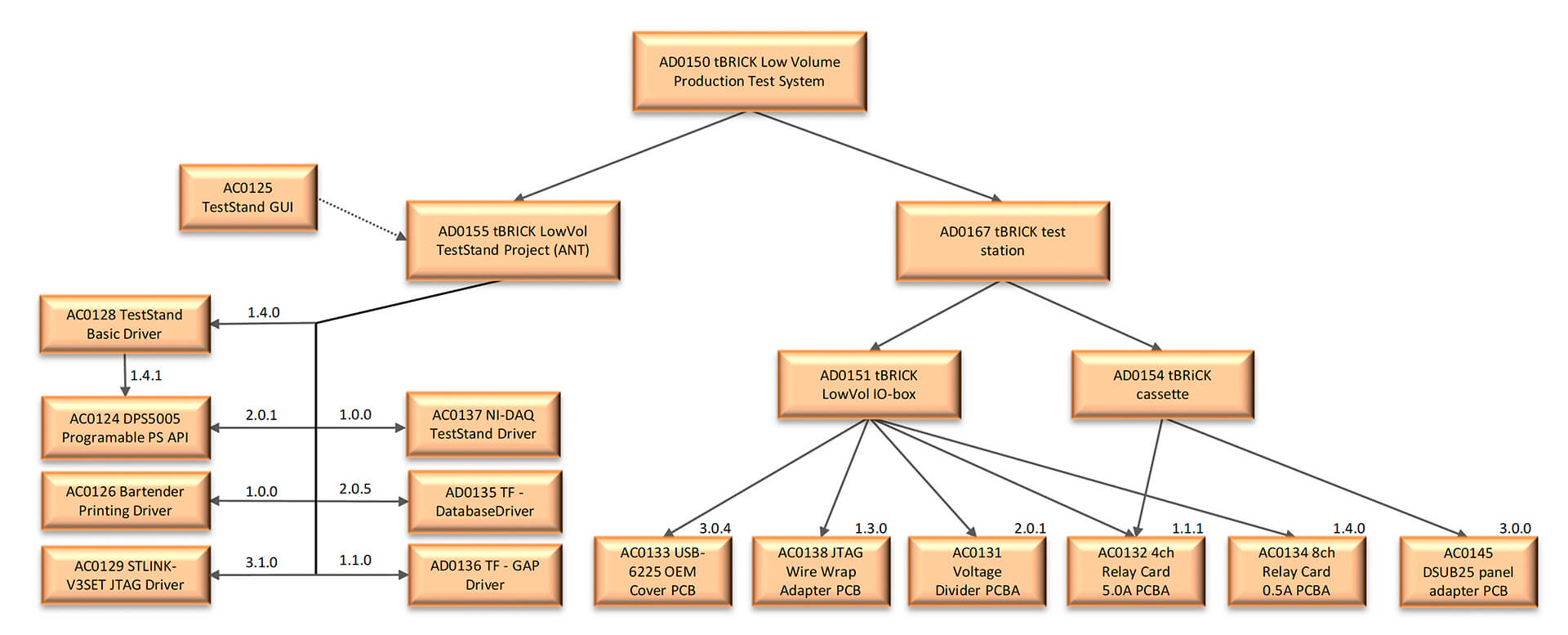

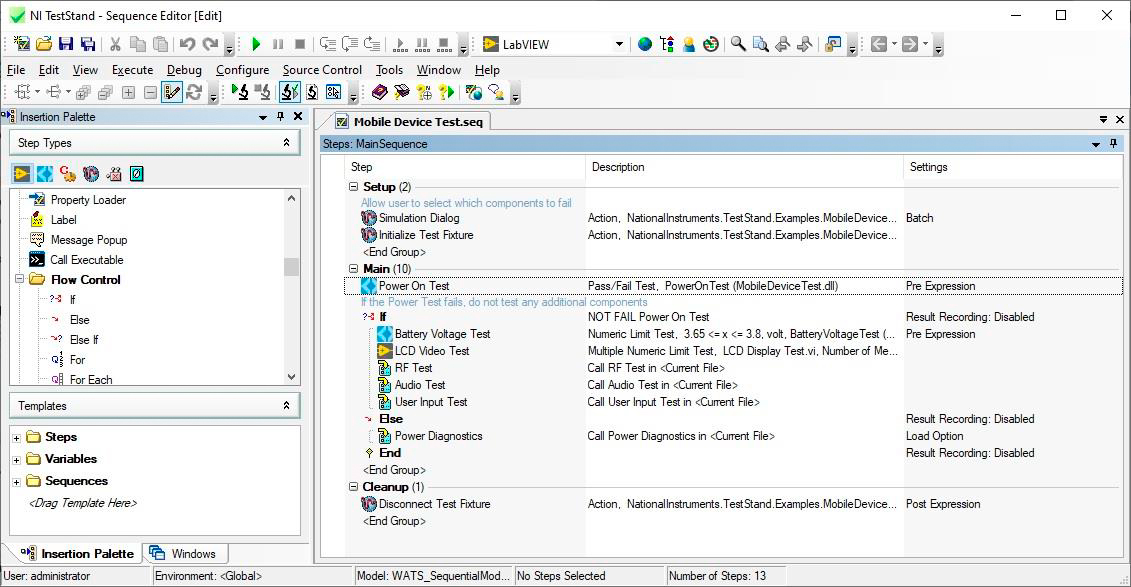

We use NI TestStand for developing a robust automated test sequence according to a test specification. TestStand provides extensible plug-ins for creating test reports, database logging, and connectivity to other systems.

We can use modules that you have developed in the test system. TestStand can integrate code modules written in most programming languages. When we design code modules for instrument control and other functions, we normally use the NI LabVIEW graphical programming environment.

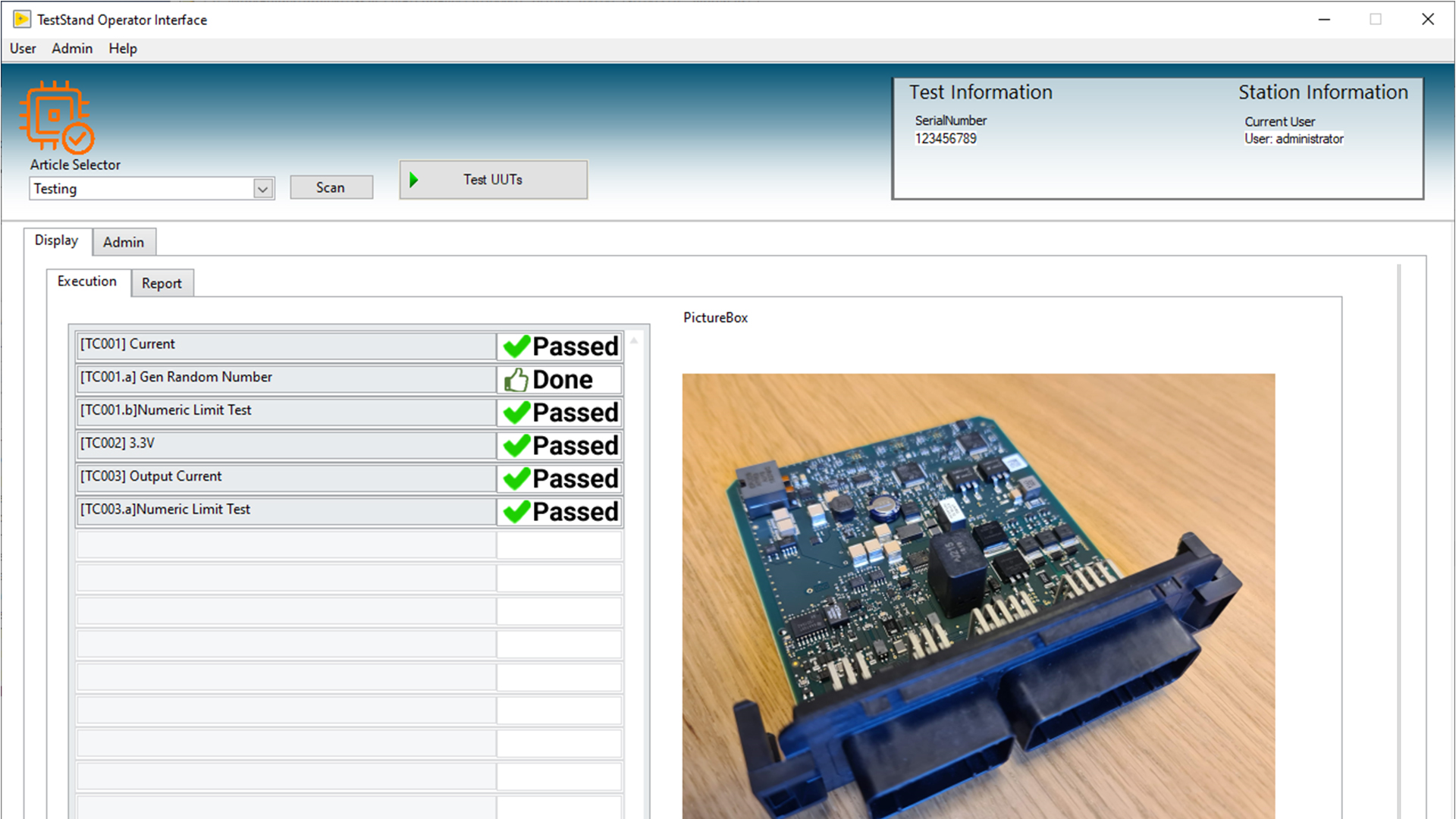

Once the test sequences are finished, it is possible to use a user-friendly Graphical User Interface, GUI, to control the test system. The GUI is easy to configure and adapt to application specific needs.

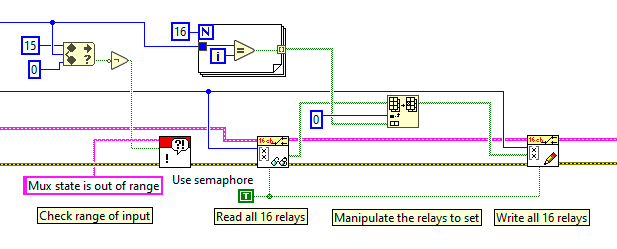

Instrument control in LabVIEW

Test sequence in TestStand

Operator control panel

About WireFlow Test Framework

WireFlow has long experience in helping companies set up test and programming environments for electronic production. We have gathered all our tools and knowledge into a versatile framework we call WireFlow Test Framework. Using our framework, we can help you to quickly develop an effective and affordable solution for testing and programming your products in the production line.

Take a look at any of the other fundamentals of WireFlow Test Framework: